The High Power Busbar XCP-HP 630-6300 Amp is an advanced and robust busbar trunking system designed to efficiently distribute high currents in demanding industrial and commercial environments. Here are the key features and characteristics of the XCP-HP 630-6300 Amp busbar:

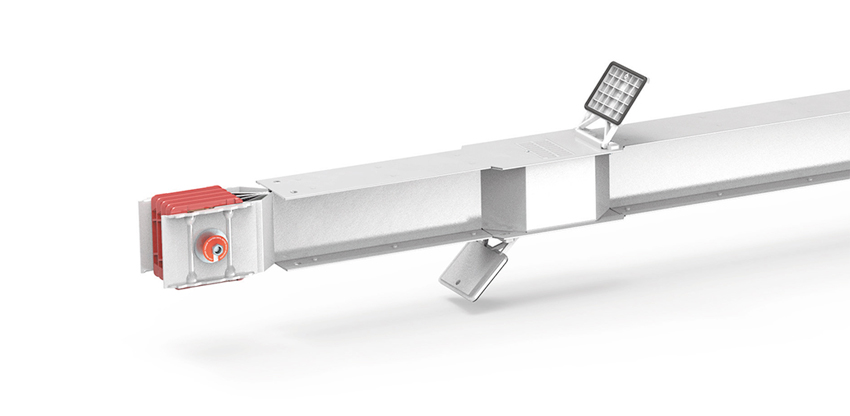

1. High Current Capacity: The XCP-HP busbar trunking system is designed to handle high currents ranging from 630 to 6300 amps. This makes it suitable for powering heavy-duty machinery, equipment, and large electrical loads in industrial facilities, data centers, commercial buildings, and power plants.

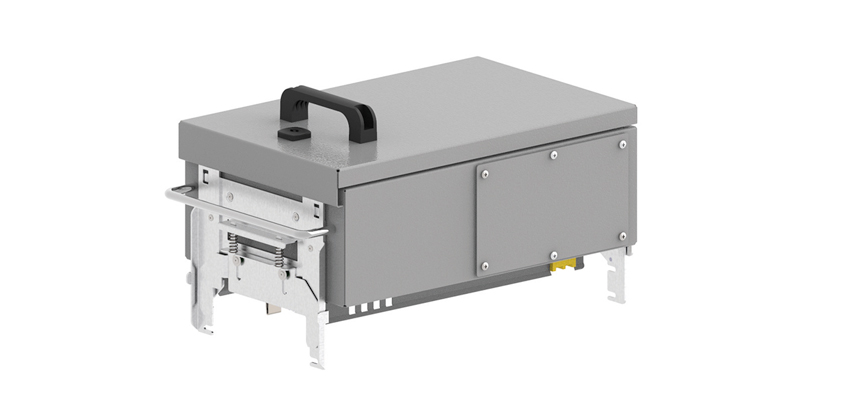

2. Heavy-Duty Construction: The XCP-HP busbar trunking system is built with durability and reliability in mind. It features a robust enclosure made of high-quality materials such as steel or aluminum, providing protection against physical damage, corrosion, and environmental factors.

3. Copper Conductors: The busbars within the XCP-HP system are typically made of high-conductivity copper, which ensures efficient power transmission with low electrical resistance. Copper conductors are also highly durable and resistant to corrosion, ensuring long-term reliability and performance.

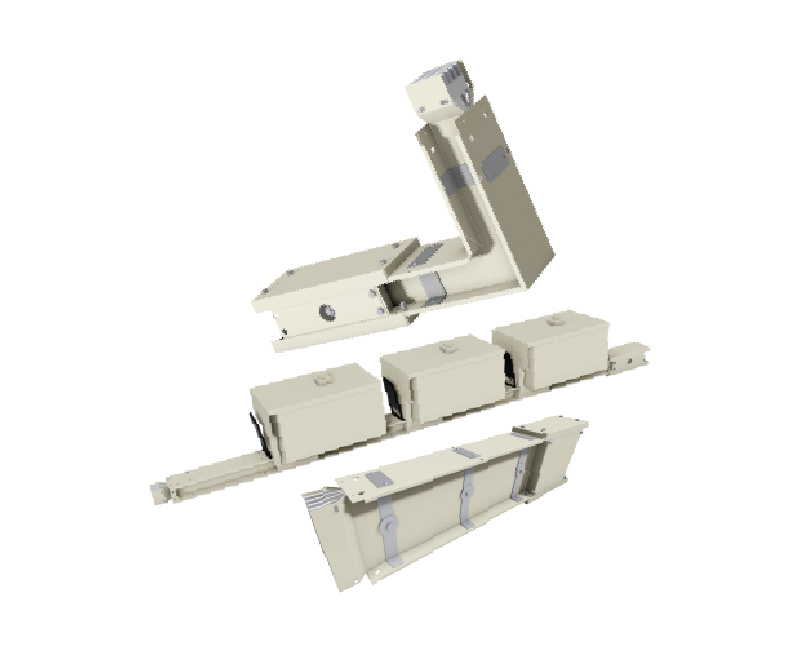

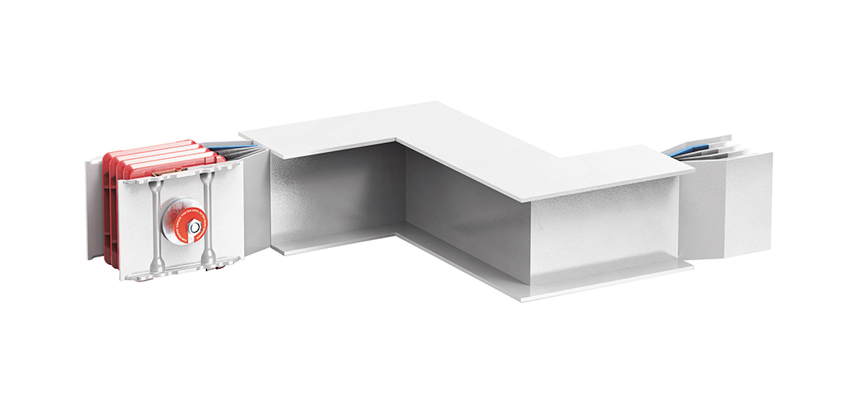

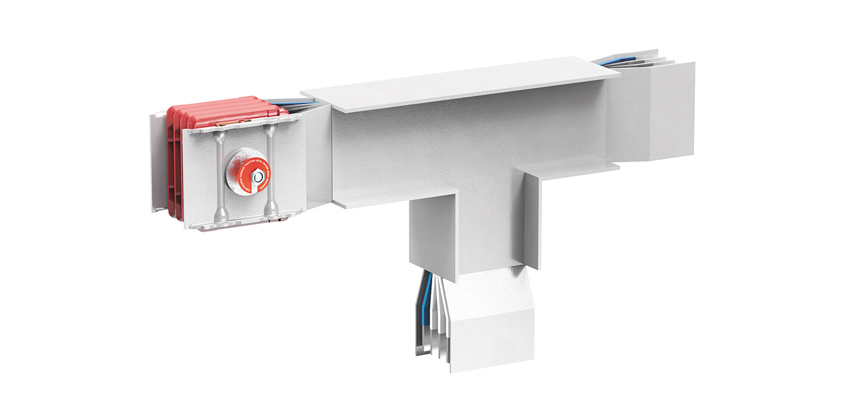

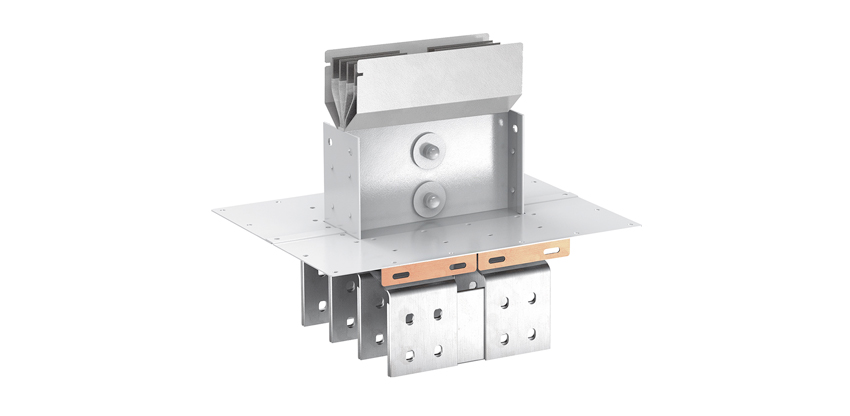

4. Modular Design: The XCP-HP busbar trunking system is modular and customizable, allowing for easy installation, expansion, and reconfiguration to meet changing power requirements. Additional tap-off units, sections, and accessories can be added as needed without the need for extensive rewiring or downtime.

5. Comprehensive Accessories: The XCP-HP busbar trunking system is compatible with a wide range of accessories, including tap-off units, joint kits, supports, and protective covers. These accessories provide flexibility in installation and allow for customization to suit specific project requirements.

6. Safety Features: Safety is a top priority in electrical distribution systems, and the XCP-HP busbar trunking system incorporates various safety features to ensure safe operation. These may include insulation, grounding, phase segregation, and protective enclosures to minimize the risk of electrical hazards.

7. Efficiency and Energy Savings: The XCP-HP busbar trunking system offers high efficiency in power distribution, thanks to its low electrical losses and short conductor lengths compared to traditional cable-based systems. This results in reduced energy consumption, operating costs, and carbon footprint over the system’s lifetime.